+86 13114821598

Pump Introductions

11. 28, 2022

The pump controller plays a decisive role in the modern water supply system. It can control the whole pumping system automatically and make the pumping process more efficient.

So what exactly is an Auto Pump Controller and what can it do for you?

Definition

An automatic pump controller is an electronic device that automatically controls the operation of the pump in a plumbing system and automatically shuts off the pump when the pressure in the system reaches a set level.

Category

The pump controller is normally separated into mechanical type and digital type.

A mechanical controller has a startup pressure and stop pressure, while the digital controller only has a startup pressure. When the pipe pressure reaches the controller’s startup value, the pump starts running. When the water tap is closed (or no water inside the pipe) , the pump stops pumping right away.

Mechanical Pressure Controller VS Digital Pressure Controller

The major difference between a mechanic pressure controller and a digital controller is that they apply different pressure regulating system. The former one uses a mechanic pressure regulator (pressure spring) and the later one uses linear pressure sensor.

The linear pressure sensor’s startup pressure ranges from 0-10bar and is adjustable, stable and accurate. While the mechanic pressure regualtor sets a fixing position of the internal spring as the starting pressure. When the tap water pressure or the building height is too high, it won’t start. Meanwhile, mechanic pressure controller has shorter service life due to the lifespan of the spring regulator. It has smaller adjusting range and not easy to regulate as well.

How does a traditional mechanical controller work?

1) The mechanical controller controls pump start and stop by startup and stop pressure. When the pipe pressure drops to the startup value, the pump starts automatically. When the pressure reaches the stop value, the pump stops running.

Problem: when the water flow is small or pump supplying water to the heater, the controller cannot detect accurately and it will cause the pump frequent start and stop. In this way, a mechanical controller is easily to damage due to the mechanical components.

2) The starting and stopping pressure needs to be adjusted manually.

When the pump doesn’t start, doesn’t stop or frequent start and stop, we can adjust the controller’s starting pressure manually through the pressure spring.

Problem: the manual adjusting is not accurate and there is limit in adjusting range.

How does the digital controller work?

A digital controller has a digital control panel and the linear pressure sensor. The starting pressure can be adjusted simply by the control panel. As the pressure range is 0-10bar, there is no limit in pump types.

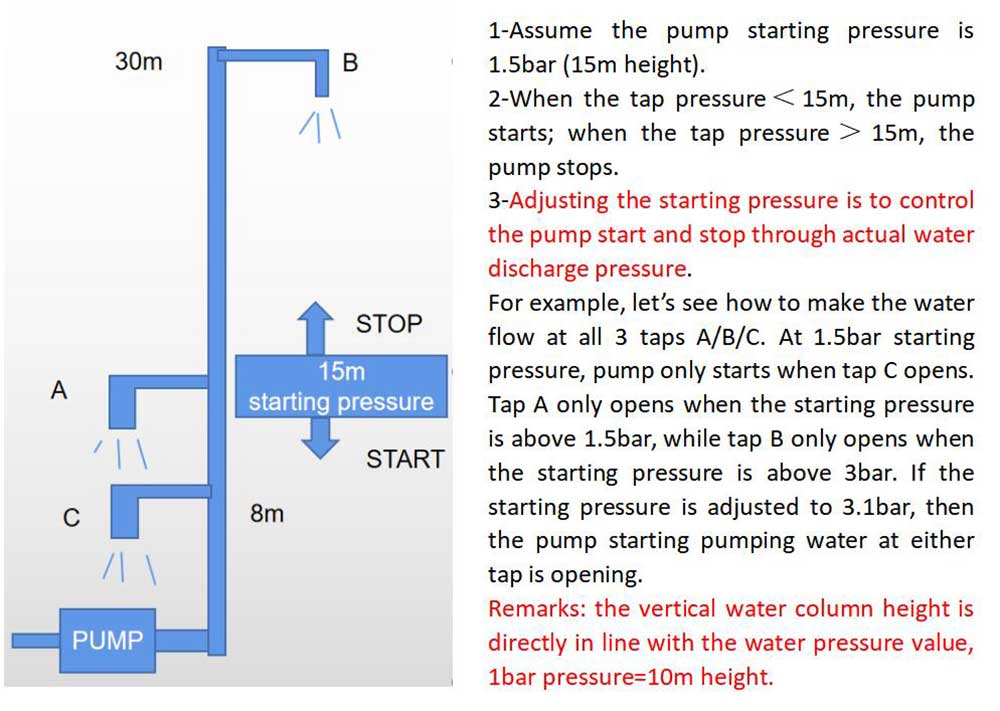

Below is the working diagram of how the pressure sensor works.

In a way, the automatic pressure controller is much more easier to operate and maintain, with longer service life. It is a top1 choice when you want to make an automatic pumping system.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13114821598

QUICK LINKS