+86 13114821598

05. 17, 2023

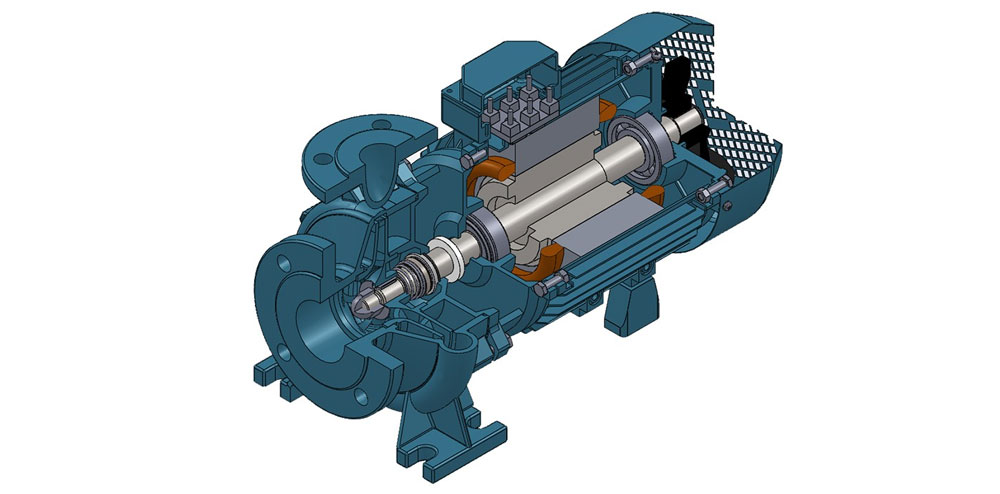

Today's dish is the monoblock centrifugal pump, a highly efficient and reliable pump used in a variety of industrial and agricultural applications. By disassembling this pump, we can gain a deeper understanding of its structure and how it functions.

Pump Structure Overview

This pump is typically close-coupled centrifugal pump as it shares the same shaft between motor and the pump from the view. Under this structure, there is less energy loss during the transmission from motor to shaft.

There are totally two major parts, the hydraulic pump and the electric motor.

Let's dissect the pump and check one by one forward.

Disrect The Pump

The hydraulic parts of a centrifugal pump play a critical role in determining the overall performance of the pump. These parts include the impeller, casing and the volute.

Firstly, the pump's outer casing is made of cast iron with electrophresis coating for durability and corrosion-resistance. This casing protects the internal components from external damage and provides stability for the pump.

The volute is a curved section of the inner casing that helps to convert the kinetic energy of the fluid into pressure. The shape and size of the volute can impact the pump's pressure and efficiency. A well-designed volute can help to increase the pressure of the fluid as it exits the pump and minimize energy losses.

pump casing and volute

The impeller is the rotating component that draws fluid into the pump and then propels it outwards. The design of the impeller, including its shape, size, and number of blades, can have a significant impact on the pump's flow rate, pressure, and efficiency. A properly designed impeller can help maximize the pump's performance and minimize energy consumption.

Remarks: Stream SEN series have gone through hydrodynamic and 3D theory design to reach the optimized hydraulic performance with high efficiency and energy saving. It allows low noise and reliable operation.

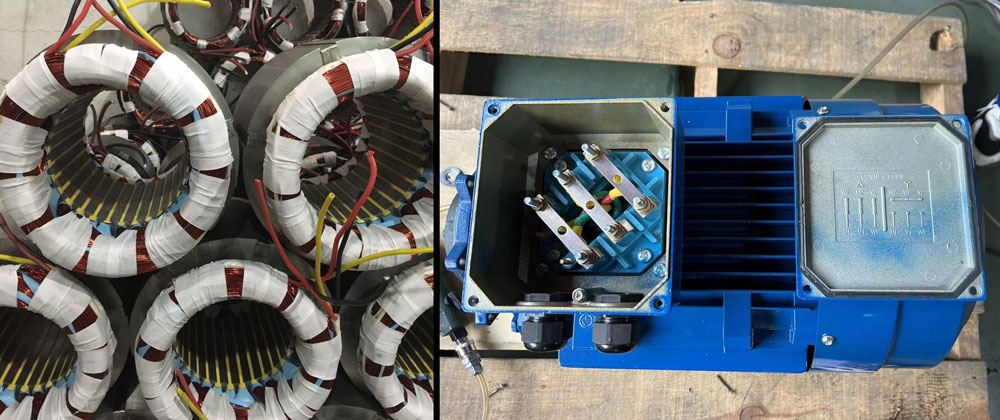

Then comes to the motor parts.

Motor can be recognized as the heart of a pump which provides power to drive the impeller and create flow. The performance of the motor can have a significant impact on the performance of the centrifugal pump as a whole. For example, if the motor is not powerful enough or is operating at the wrong speed, it may not be able to generate the necessary flow rate or pressure to meet the needs of the application. Similarly, if the motor is not properly maintained or serviced, it may be more prone to failure, leading to downtime and decreased productivity.

In addition, the energy efficiency of the electric motor is an important consideration when selecting a centrifugal pump. Motors that are designed for high efficiency can help to reduce energy consumption and lower operating costs over time.

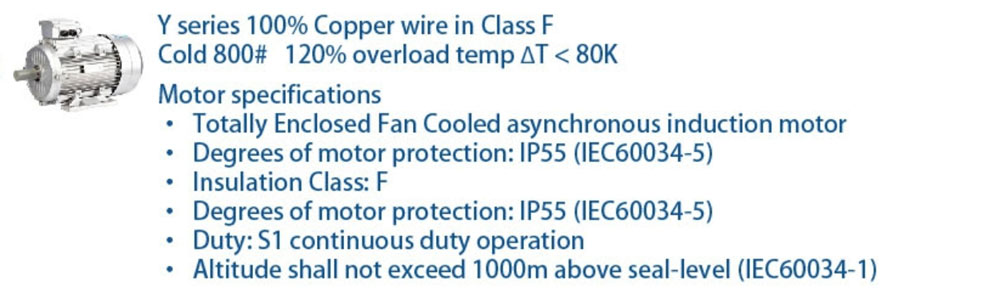

Remarks: Stream SEN series are supported with Y series high efficiency motor with below features.

The pump also features a mechanical seal, which prevents fluid from leaking out of the pump. The mechanical seal is a critical component that requires regular maintenance and replacement to ensure the pump's optimal performance.

In addition, the pump also have a variety of components like bearings, flanges, brackets, foot and fan cover which together form the pump's performance.

By disassembling the monoblock centrifugal pump, we can see how each component works together to create an efficient and reliable pumping system. This deeper understanding allows us to provide valuable insights to customers and recommend the best pump for their specific needs. So, if you're in the market for a centrifugal pump, consider the monoblock design and the benefits it can offer for your application.

Stay tunned and we'll share more knowledge from factory direct.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13114821598

QUICK LINKS