+86 13114821598

Pump Knowledge

03. 11, 2024

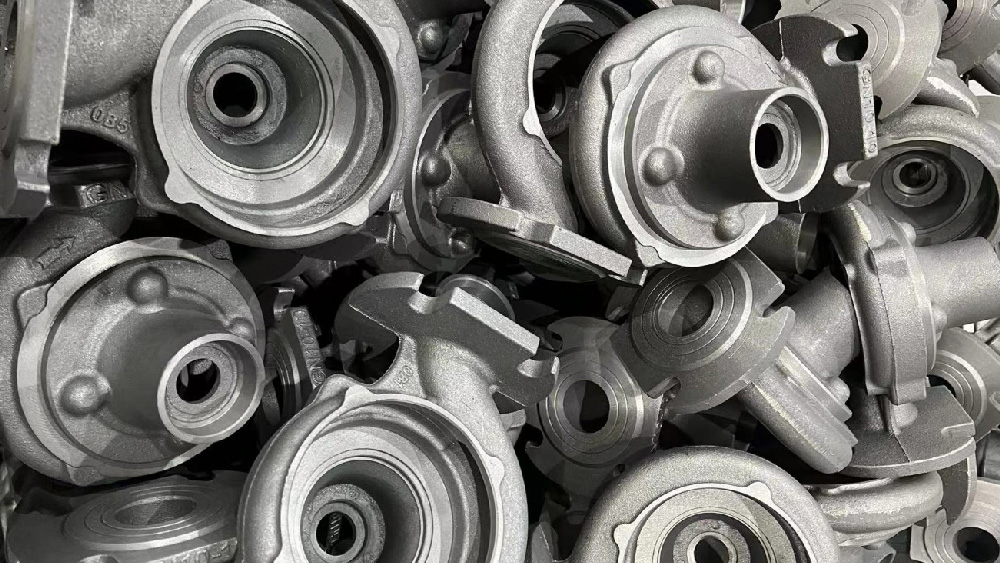

Just like great food starts with top-notch ingredients, quality water pumps begin with careful control of their building blocks. Let's talk about how the material used in water pump castings plays a crucial role in extending the pump's lifespan.

Begin with the basics: the selection of the right raw materials lays the foundation for an exceptional pump. Employing fine sand as the primary component establishes a robust groundwork, contributing not only to the pump's durability but also to its aesthetic appeal.

Stream has it's own foundry shop which can control its own casting quality as well as providing customized solution for OEM customers.

Yet, it's more than just about the ingredients; the crafting process itself is equally significant. The infusion of iron and copper adds resilience during manufacturing, ensuring the pump can withstand challenges and continues to operate reliably over an extended period.

The commitment to excellence doesn't conclude with crafting; a meticulous polishing stage eliminates rough edges, providing the finishing touches. The outcome is a pump that not only boasts a smooth, flawless surface but also exudes a high-quality feel, promising longevity.

Further enhancing the pump's durability, the electrophoresis of cast iron parts adds corrosion resistance, extending the pump's overall lifespan.

However, the journey doesn't end there; the castings require preservation for over six months before stabilizing and becoming ready for pump assembly.

It is through these meticulous procedures that our pumps emerge, marrying an appealing exterior with inner strength to tackle heavy-duty tasks.

Previous: None

Next: The Guide to the Functionality and Importance of Submersible Pump Accessories

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13114821598

QUICK LINKS